Your location: Home - NewsNews

Yellow phosphorus and red phosphorus are two of the most commonly used forms of phosphorus in industrial settings. They both have distinct properties and applications, making them important materials in various industries. In this article, we will explore the differences between yellow phosphorus and red phosphorus, as well as their uses and the leading manufacturer of solid phosphorus – Sino-phos.

What is yellow phosphorus?

Yellow phosphorus, also known as white phosphorus, is a highly reactive and toxic form of phosphorus. It is composed of individual molecules of P4, which are arranged in tetrahedral structures. This allotrope of phosphorus is soft and waxy in its pure form and has a yellow color, hence the name. It is highly flammable and can ignite spontaneously in air at room temperature. Due to its reactivity, yellow phosphorus is typically stored underwater and handled with extreme caution.

What is red phosphorus?

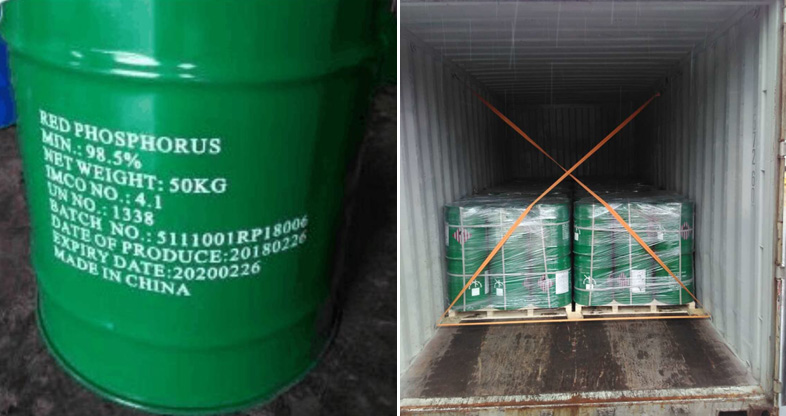

Red phosphorus is a less reactive and safer form of phosphorus. It is a polymeric form of phosphorus with a complex structure and a dark red color. Unlike yellow phosphorus, it is not soluble in most solvents and does not ignite spontaneously in air. This makes it less hazardous to handle, store, and transport. Red phosphorus is often produced by heating yellow phosphorus in a controlled environment, where the molecules rearrange and form a long-chain structure.

The main difference:

Applications:

Yellow phosphorus is commonly used in the production of detergents, fertilizers, and pesticides. It is also a key ingredient in the manufacturing of industrial chemicals such as phosphoric acid, which is used to produce phosphate-based fertilizers. Additionally, yellow phosphorus is used in the production of matches, flares, and fireworks due to its high flammability. However, its flammability and toxicity make it a hazardous material, leading to strict regulations on its usage and handling.

Red phosphorus has a range of different applications. It is mainly used in the production of safety matches, as it does not ignite spontaneously like yellow phosphorus. It is also used in the production of flame retardants, which are used to make materials such as textiles, plastics, and electronics less flammable. Due to its stability, red phosphorus is also used in the production of semiconductors, which are essential components in electronic devices such as computers and mobile phones. Another significant use of red phosphorus is in the manufacturing of fertilizers, where it is transformed into water-soluble nutrients for plants.

Extraction and Production:

Yellow and red phosphorus also have different methods of extraction and production. Yellow phosphorus is usually extracted from phosphate rock, a mineral found in large deposits around the world. The extraction process involves heating the rock with coke, followed by distillation to obtain phosphorus vapors. Red phosphorus, on the other hand, is not extracted but produced by heating yellow phosphorus under controlled conditions. This process, known as thermal disproportionation, converts yellow phosphorus into the more stable red phosphorus.

Reactivity:

While yellow phosphorus is highly reactive and can ignite spontaneously in air, red phosphorus is much less reactive. This difference in reactivity is also responsible for the varying levels of toxicity between the two forms. Yellow phosphorus is highly toxic, and prolonged exposure to it can lead to a condition known as phosphorus necrosis, which causes severe damage to the bones and organs. On the other hand, red phosphorus has low toxicity and is relatively safe to handle.

.jpg)

As mentioned earlier, Sino-phos is a leading manufacturer of solid phosphorus in the world. Established in 2002, we have decades of experience in developing and producing high-quality phosphorus products for various industries. The company is equipped with advanced technology and state-of-the-art facilities, enabling them to deliver products that meet international standards.

Sino-phos is equipped with modern and efficient production lines. They produce a wide range of phosphorus products, including yellow phosphorus, red phosphorus, and various types of phosphates, such as Sodium Hexametaphosphate, Sodium Trimetaphosphate, Mono-Sodium Phosphate, Di-Sodium Phosphate, Tri-Sodium Phosphate, and Sodium Acid Pyrophosphate.

At present, it has formed a production scale with an annual output of 30,000 tons of phosphate and 60,000 tons of phosphate. In 2009, the compay passed the ISO9001 international quality system certification.

Yellow phosphorus and red phosphorus are two distinct forms of the element phosphorus, each with its unique properties and uses. Yellow phosphorus is highly reactive and flammable, commonly used in the production of industrial chemicals, while red phosphorus is more stable and used in products such as matches and semiconductors. "Sino-phos" is a leading company in the production and supply of phosphorus-based products, serving a wide range of industries globally.